More emphasis is rightly being placed on developing sustainable and environmentally friendly packaging solutions. While single-use coffee cups are easily replaced with reusable ones, other types of everyday packaging are more difficult to replace.

Nonetheless, innovative packaging manufacturers are working to develop solutions that can replace and outperform more traditional uses. Paper honeycomb packaging material and its variants are one such example. We’ll look at some of the advantages provided by this revolutionary packaging material, which is increasingly being used in cardboard boxes.

What Is Honeycomb Paper Packaging?

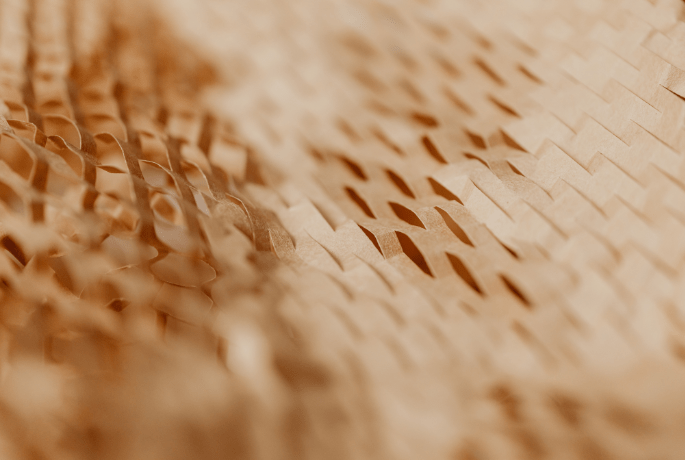

Paper honeycomb is a long-lasting, lightweight, and cost-effective packaging solution made from kraft paper. Inspired by nature, the one-of-a-kind panels typically include a honeycomb core, similar to that found inside a beehive, as well as two surface-covering materials that sandwich it.

The resulting paper honeycomb panels have numerous applications in the packaging industry, some of which will be discussed in the second part of this two-part post series.

Paper Honeycomb Packaging Benefits

Extremely tough

“How strong can a packaging solution made of paper in a honeycomb formation be?” you may be wondering. Paper honeycomb packaging material is an outstanding innovation because it is stronger than steel pound for pound. The honeycomb core and sandwich layers act as a traditional steel I-beam, which is commonly used in construction and civil engineering applications. Paper honeycomb becomes even stronger when combined with other materials such as plastic, fibreglass, or metal. This type of box, like our foam-lined boxes, is frequently used for transporting more delicate technologies.

Extremely lightweight

Unlike steel, paper honeycomb is extremely lightweight and has a higher strength-to-weight ratio than many other materials. This is why it is such an excellent choice for packaging applications. Paper honeycomb packaging material allows businesses to significantly reduce the weight of their shipments while still benefiting from the durability and protection it provides.

It is completely recyclable

Paper honeycomb packaging material is 100% recyclable in addition to having all of the properties listed above. In fact, it is typically made from renewable and recycled paper that has been glued together with a water-based adhesive. Paper honeycomb uses significantly less paper in its construction than traditional cardboard and corrugated cardboard. However, the reduction in paper does not reduce its strength; in fact, paper honeycomb has an impressive compressive strength of 7 kg/cm2.

Cost-effective

Paper honeycomb is often less expensive to produce and thus purchase because it uses less material than many traditional packaging solutions. Furthermore, because of the associated savings in shipping and handling fees, businesses frequently save more than once when using paper honeycomb.

Customizable

While paper honeycomb is commonly found in panels and pallets, its applications are not limited. In fact, paper honeycomb panels are frequently die-cut to the exact shapes and sizes required by businesses. This allows all kinds of products to fit snugly inside them and is ideal for businesses that only make a few different products. A simple slit on the reverse side of the honeycomb panel allows it to be easily bent and formed around objects.

Industrial Applications

Here are some examples of how paper honeycomb packaging and its durable, lightweight design are used in various industries around the world:

Automotive Industry

Paper honeycomb packaging material is commonly used for shipping parts in the automotive industry. Everything from engines and headlights to bumpers and filters can be shipped using die-cut paper honeycomb packaging. Returnable packaging is frequently prohibited for this application due to the high costs involved. Paper honeycomb is not only used for shipping car parts but it is also being incorporated into actual automobiles.

Ford Motor Company unveiled a new parcel shelf in January of this year, made with a honeycomb design, water-based glue, and durable fiberglass sandwich layers. According to Ford, the resulting product can support 100 times its own weight and improves fuel efficiency.

Furniture Industry

You might not realize it, but paper honeycombs are used in the design of a lot of wooden furniture. Furniture manufacturers can reduce their reliance on limited natural raw materials by sandwiching paper honeycomb between wooden boards. The finished weight of the product is also reduced, all while maintaining the piece’s durability, rigidity, and longevity. Paper honeycomb packaging material is then used to ensure that the piece of furniture is delivered in its entirety to the end user.

Global Transport Industry

Scania, a Swedish commercial vehicle manufacturer, worked with packaging pioneer Smurfit Kappa to revolutionise supply chain packaging without jeopardizing the safety of some of their more fragile products. Scania used four different materials for transporting its large truck windows at the time, including wooden pallets and expanded polystyrene (EPS). Smurfit Kappa devised a solution that substituted a completely sustainable, paper-based honeycomb for the wooden pallets and EPS. The mono-material solution uses a paper honeycomb pallet and a partnering cover to keep the windows safe. Scania reduced storage space by 50% while also reducing the number of materials used in the packaging process.

Textile Industry

Textile manufacturers can send precious materials, such as silk bobbins, all over the world by using paper honeycomb panels with small holes drilled or die-cut into them. The lightweight and robust paper honeycomb packaging ensures that the cargo is kept safe at all times and that no additional shipping charges are incurred. Furthermore, because the honeycomb panels have been cut with custom holes, the packaging can be reused multiple times, saving both money and the environment. As demonstrated by the examples above, paper honeycomb is an extremely versatile packaging material that can be applied to a wide range of applications in a variety of industries.

To reduce their carbon footprint, most industries are embracing sustainability. Because of its durability, eco-friendliness, and lightweight qualities, honeycomb packaging material has a wide range of applications in a variety of industries. Honeycomb packaging is gradually replacing other packaging materials such as PUF, MDF, bubble wrap, EPE foam, and particle boards due to its flexibility and environmental friendliness. One of Ficus Pax’s most popular products is honeycomb packaging, which is an eco-friendly, cost-effective, lightweight, and strong material.

Want to learn more about the advantages of using honeycomb packaging material for your products? Get in touch with us at https://ficuspax.com/contact/