Manual Automated Material Handling is a critical component of any logistics or manufacturing project. There are numerous industrial packaging solutions available; however, the majority of physical commerce items are transported using tuggers, trains, and carts. This blog will look at the role of various material handling equipment and how to implement efficient material handling solutions, including their types, fundamentals, and designs.

What exactly is material handling?

For many large corporations, effective material handling is at the heart of all operations. Transporting materials, work in progress, and finished goods from one area of the facility to another is critical to the safety and success of their operations. Furthermore, the material handling process includes material movement, protection, storage, and control.

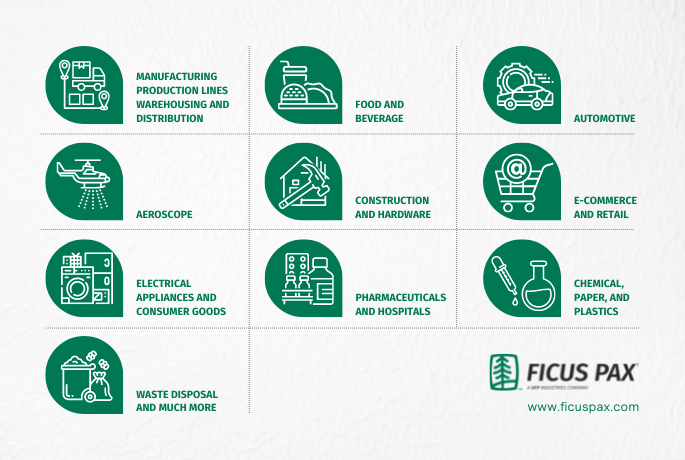

This procedure is used in the following industries:

Ensuring safety in workplaces where material transportation occurs is also becoming increasingly important in most industries. Material handling processes that are efficient can significantly reduce accidents.

What are the different kinds of material handling?

There are two types of material handling that operators and business owners should be aware of.

And here are some examples:

1. Manual material handling

Workers use their hands to move individual containers in manual material handling. When transporting containers, they lift, lower, fill, empty, or carry them. However, this can be dangerous for workers because it exposes them to potentially hazardous physical activities.

2. Automated material handling

When economically and technically feasible, equipment is used to reduce or replace manual material handling. Indeed, many of today’s material handling machines are semi-automated due to human operator needs such as driving, unloading, or loading containers.

What are the fundamentals of material handling?

It is critical to understand the principles involved in material handling processes.They are as follows:

- Orientation: Prior to preliminary planning, this principle encourages assessing any available system relationships. It may include an assessment of the problems and existing industrial packaging solutions.

- Planning: Planning should include the fundamental requirements, contingency planning, and other desirable alternatives. A collaborative approach involving consultants, suppliers, and users is required for successful planning.

- Systems: This principle should incorporate cost-effective Manual Automated Material Handling activities into the system. The entire supply chain, including suppliers, distributors, manufacturers, and customers, should be addressed by system integration.

- Unit load: A unit load is a load you can store or move as a single entity, such as a container, tote, or pallet. It is a single load, regardless of the individual items that make it up.

- Space utilization: This principle encourages the efficient use of available space. It is a three-step process that involves eliminating unorganized and cluttered areas, balancing the aim of maximizing storage density and accessibility.

Types of Material Handling Equipment and Their Applications

Many businesses that need to handle and store bulk materials rely on material handling equipment and systems. Material handling equipment, in general, refers to equipment designed to move, control, protect.

1. Material Handling Equipment in Bulk

Bulk material handling equipment includes machinery for transporting, storing, and controlling bulk materials.

2. Systems Engineered

Engineered systems, also known as automated systems, are automated bulk material handling equipment used to transport and store materials.

3. Heavy-Duty Trucks

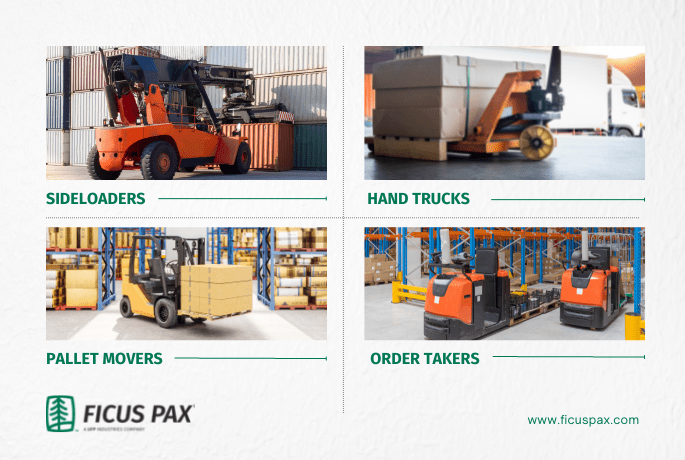

Industrial trucks cover a wide range of equipment and are all intended to aid in material transportation. These industrial trucks can range in size from small, hand-operated machines to large, driveable machines.

4. Storage and Handling Equipment

Storage and handling equipment aids in the safe storage and organization of materials while they await another stage in the manufacturing or distribution process. Depending on the needs of the company.

Material handling equipment has a variety of applications

Many companies in various industries use material handling equipment because of the wide range of machinery and equipment it covers. Here are some examples of how material handling equipment is used in various industries:

Why Is Material Handling Equipment Important For Your Business?

Material handling equipment can greatly benefit companies in diverse industries. Many companies enjoy how material handling systems and equipment improve their workplace’s efficiency and safety. Additionally, material handling equipment can reduce waste, lower costs and optimize a facility’s space. Here are some of the most significant benefits of using material handling equipment:

- Greater efficiency

- Reduced waste

- Lower costs

How to Choose the Best Material Handling Equipment for Your Needs

With all of the advantages of using bulk material handling equipment, you may be interested in purchasing some for your facility. Learn more about the main factors to consider when deciding on the best equipment for your needs:

- Type of material

- Production flow Facility layout

- Types of operations

- Expense

- Factors of structure

- Reliability

Automation is the future

The ongoing transition to a smarter work or manufacturing environment is also dependent on proper material handling. Again, using semi-automated or fully automated systems is the way to go here. The advantages of this material handling solution include decreased downtime and faster just-in-time delivery and production. When materials are handled properly, the number of lost or damaged materials is reduced. Furthermore, methodical and efficient material handling promotes a cleaner work environment.

Ficus Pax is the place to go for all your industrial packaging solutions.